SAME-DAY COSMETIC CROWNS

3D Precision Milling

Using technology similar to a 3D printer, our milling chamber precision mills the all-ceramic (metal-free) crown with accuracy measured in microns. A custom shade analysis helps us to select the ceramic material that will best match the natural color and unique translucency of your teeth. We use digital macro SLR photography as well as a digital spectrophotometer to make natural-looking restorations.

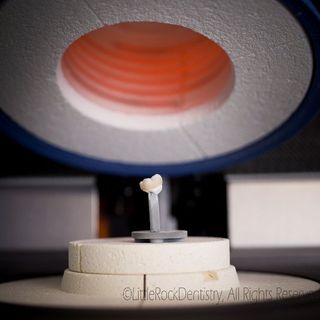

Hand Finishing and Characterization

After the 3D precision milling is complete, we hand-finish the ceramic in our laboratory with diamond polishing, color enhancements and ceramic glazing to mimic the natural characteristics of your teeth. We really enjoy the "craft" of this process and love to make ceramic crowns that blend in with your natural teeth.

In-House Ceramic Glazing

After hand-finishing, the crown is glazed in our software-programmed ceramic oven for the porcelain to obtain its final luster and strength. The ceramic oven is similar to a "kiln" used to create artwork and pottery.

Crown Placement

We want your new teeth to fit well and look great! After the new crown is bonded in, you should be ready to eat and drink as soon as the numbness wears off. In most cases, the numbness from the procedure wears off shortly after the final restoration is cemented.

We really enjoy this digital process and think the technology is fascinating! Please give us a call and we would be happy to address any questions that you may have. Thank you!

We really enjoy this digital process and think the technology is fascinating! Please give us a call and we would be happy to address any questions that you may have. Thank you!